MicroCare Medical has earned success selling its Swellex silicone swelling fluid to companies assembling medical tubing. Here’s how it works.

“That’s because the swelling fluid helps workers reduce the amount of force needed to insert a tube onto a barb or other type of connector,” David A. Ferguson, senior market and technical manager at MicroCare, told Medical Design & Outsourcing.

Whether the manufacturing involves assembling IV tubes and bags, drainage catheters, dialysis machine tubing or a host of other products with tubing, companies are avoiding having to throw out tubing because of stress cracks, according to Ferguson. Swellex is also helping employees avoid carpal tunnel, wrist problems and other workplace-related injuries.

“Since you don’t want to introduce heat, glue or anything else that can affect the integrity of the tubing or has to be qualified with the FDA, tubing is typically assembled by hand. Swellex helps make it easier,” said Ferguson, who spoke with MDO during MD&M West early this year.

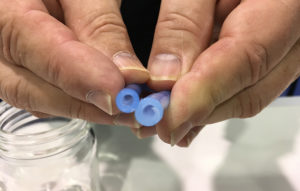

A worker can soak a dozen tubes in Swellex for 10 to 15 minutes – until the inner diameters of the tubes soften and swell enough that they can be easily attached, Ferguson said. The tubes then contract to their original shape, size and strength, forming a tight, leak-proof grip as the Swellex quickly evaporates.

The process produces no residue affecting the qualification of the manufacturing process under FDA guidelines, according to Ferguson. Because the swelling fluid’s active ingredient is a methyl siloxane — a member of the silicone family — it doesn’t affect the integrity of the tubing, he said.

Much of the use for Swellex involves tubing made of silicone rubber, a go-to material for medical tubing. The swelling fluid, however, is compatible with other tubing materials, including polyethylene and polyimide, but prior in-use testing is important, Ferguson said. MicroCare also has a second swelling agent called Swellex P, a proprietary formulation that works on polyurethanes.

Ferguson acknowledged that there are a few challenges manufacturers should address before using Swellex:

• Out-gassing can take up to 24 hours. Ferguson has found this often isn’t a problem for tubing manufacturers. “In most applications, this is an intermediate step. You’re doing more to the component than just assembling the tubing, so it will de-gas while you’re performing other tasks.”

• Swellex is flammable, but medical tubing manufacturers generally only use about a liter at a time. “It’s no more of a challenge than having a little bit of IPA,” Ferguson said.

• The fluid does pull some oils out of the skin. The recommendation is that workers wear gloves when assembling tubing.

Overall, Swellex has been a best-seller for MicroCare. “After qualifying Swellex and seeing how it can speed assembly and throughput, many companies recommend it for their other divisions, Ferguson said. “Swellex is rapidly expanding throughout the medical manufacturing industry.”